Overview

Architects play an important role in new construction and renovation of building or old structures. An architect develops the facility program of building owner and assembles the design team who contributes to the success of the project.

An architect designs the smart building and indicates how the process would be to carry out the aesthetics of a smart building. They understand how important it is to monitor, control, and automate systems to build a smart building. All these systems contribute to a facet of the building that adjusts to the building’s environment and operational performance to look into safety measures, comfort, sustainability, and healthy atmosphere.

Smart buildings or intelligent building does not only depend on control and automate systems; it heavenly depends upon fixed attributes of the buildings such as initial siting, the structure, windows and interior layout in how buildings would operate and functions.

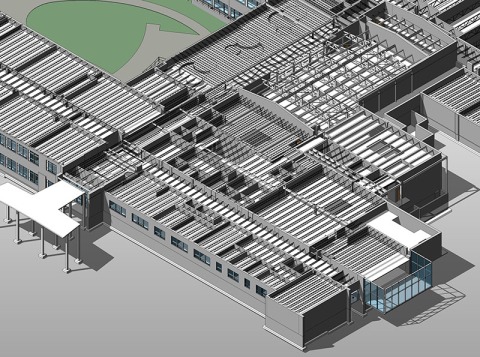

An intelligent building is designed in a way that depicts the present and future needs of occupants living in it and enhances knowledge and how designers or planners use its intelligence. Architectural BIM Services helps the designers to perform complete design in detail by using BIM Model for representation purpose of showing clients how the building will look like once built in real and about object placements.

Facility Programming

Development of a facility program is done by an architect in collaboration with engineers, consultants, facility programmers, and manufacturers. Designing intelligent building is a creative and iterative process where the owner’s objective, values, and preferences and the need for aesthetics, economic, energy analysis, and sustainability.

Few features of the facility program will be soon mandated by government intervention, among which one is the LEED certification program. Smart Building Institute (SBI) will give certificate based on advanced technology, system and data integration, building operations which describe the detailed framework and properties of the intelligent building.

Design Teams

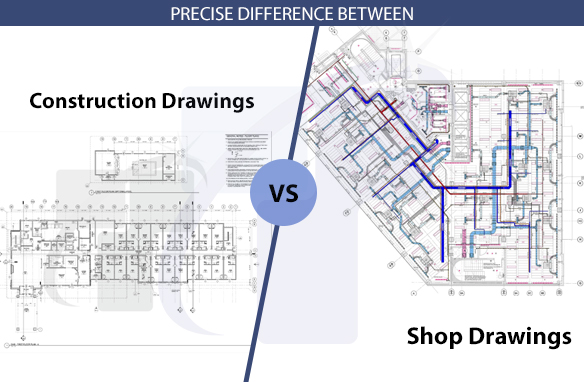

Facility program is transformed into a detailed design where the team determines the design requirement, specifies and draws up the project, produces the construction document, and administers the construction contract.

For constructing a smart building, it is necessary that the architects must select appropriate design team that is creative, innovative, technology saved and experienced. Designers must be upgraded to make buildings as per standards and keeping in mind the environment, and the architect must know how to deal with complex buildings.

Siting the Building

Architects in today’s era are helping the owner’s in selecting and venturing new site for construction purposes or existing building survey. Selecting a site is a very important aspect of the smart building as the design will be affected by the specification of a site, topography, climate, and public utilities.

Materials

Architects and design team inspects about what materials will be used in the building. Materials do deteriorate and wear out and often results in condensation, corrosion, stains, fungus, and other negative properties. It affects the ongoing cost and ease of maintenance, repairing, and replacing services. Selection of material must think of utilizing the long-term use and cost of the materials and minimize the maintenance through standard products.

Conclusion

The intelligent building does contribute to the design concept and impacts the level of efficiency to suit the needs of occupants. Architects and BIM Services Modelers must update themselves regularly to standards, designs, regulation, and policies. The material must be carefully read and understood to implement the construction of smart buildings. It has to mainly look forward to sustainable and energy analysis of the building.